Friday, April 9, 2010

PID Heater control with any Arduino

I've been controlling the temperature of my extruder with a super simple (yet very functional) Arduino-based controller. To control your heater with any Arduino-alike you only need to add one resistor and one FET. It doesn't get any easier than that!

I used my Arduino compatible Fabio board, but anything should work. Get the full scoop and code on the Makeyourbot wiki.

Wednesday, April 7, 2010

Youtube + Time = CNC Milling Machine...

We shipped out the first six Mantis 9 machine kits yesterday to locations all around the world.

Thus far I've personally helped everyone that has put together a Mantis machine. But now the machines have flown the coop, so I created a series of 13 videos showing how to get the X, Y, and Z axes completely assembled. The next sequence of videos (in work) will show how to install the motors/leadscrews and leave you with a finished machine!

I've also uploaded photos of the A3982 stepper driver board, and the new 4 axis/spindle controller.

Enjoy the videos, and stand by for more to come.

-DC

Thus far I've personally helped everyone that has put together a Mantis machine. But now the machines have flown the coop, so I created a series of 13 videos showing how to get the X, Y, and Z axes completely assembled. The next sequence of videos (in work) will show how to install the motors/leadscrews and leave you with a finished machine!

I've also uploaded photos of the A3982 stepper driver board, and the new 4 axis/spindle controller.

Enjoy the videos, and stand by for more to come.

-DC

Sunday, April 4, 2010

Parallel rod construction video!

Last time I talked about how to create exactly parallel rods for sliding machine axes. To make it a bit more clear, Sean (another Media Labber), my Aussie friend Owen, and I created a quick video that shows the construction of a Mantis 9 Y axis. Check it out...

As much as I'd like for it to, not everything goes to plan in these videos. Here's our first blooper.

More videos soon.

As much as I'd like for it to, not everything goes to plan in these videos. Here's our first blooper.

More videos soon.

Thursday, April 1, 2010

The secret to exactly parallel rods...

...is coming up in a minute ;)

Firstly though, the machines are multiplying!

The new machine on the left is version 9.1 of the Mantis mill. It has a few design fixes and general improvements over the original machine on the right.

The 9.1 machine isn't going to be the newest for very long though. Fellow hackers at six of the Fab Academy Fab Labs around the world will be receiving parts kits next week! The Fab Labs participating are:

I updated the Mantis 9 wiki page with a bunch of new construction photos and a description of the process used to get sets of axis guide rods exactly parallel. The best part is that no fancy tools are required, and you don't even have to measure anything!

Firstly though, the machines are multiplying!

The new machine on the left is version 9.1 of the Mantis mill. It has a few design fixes and general improvements over the original machine on the right.

The 9.1 machine isn't going to be the newest for very long though. Fellow hackers at six of the Fab Academy Fab Labs around the world will be receiving parts kits next week! The Fab Labs participating are:

- AS220 - Providence, RI - USA

- Fab Lab Barcelona - Barcelona - Spain

- Fab Lab Bermeo - Bermeo - Spain

- Fab Lab Nairobi - Nairobi - Kenya

- Fab Lab Vestmannaeyjar - Vestmannaeyjar - Iceland

- Waag Society - Amsterdam - The Netherlands

I updated the Mantis 9 wiki page with a bunch of new construction photos and a description of the process used to get sets of axis guide rods exactly parallel. The best part is that no fancy tools are required, and you don't even have to measure anything!

Saturday, March 27, 2010

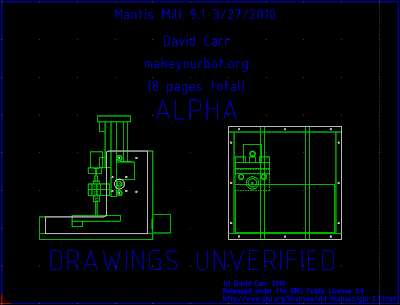

Mantis 9 DIY Build Preview

I just finished putting together a set of DIY build templates for the Mantis Mill 9. The basic idea is that with this PDF, a handsaw, a drill press, and a bit of sweat anyone should be able to build their own machine.

PLEASE DO NOT BUILD ANYTHING FROM THESE DRAWINGS YET!

There a several design modifications from my prototype that I want to test before anyone starts cutting wood. That said, the zipfile is on the wiki.

Thursday, March 25, 2010

The future lives!

Today Mantis machine number 9 came to life!

It's first project was a Fabio (arduino compatible) controller like that used in my extruder heater controller.

The board itself came out very well. V9 has reduced slop in the Z axis, an issue that plagued the V8 and earlier machines.

Notice that the trace edges look very clean with few if any burrs. The lower right looks especially good probably because that's where I zeroed the mill. Hopefully after I flatten out the table, the whole board will look like that.

Mantis 9 is radical departure from my earlier designs--- it has parallel rod axes for example, but I think it turned out very well. Most importantly its the simplest design yet, with only 12 parts! Also I think it might be the first design completely reproducible without machine tools. More details to follow soon on the wiki...

It's first project was a Fabio (arduino compatible) controller like that used in my extruder heater controller.

The board itself came out very well. V9 has reduced slop in the Z axis, an issue that plagued the V8 and earlier machines.

Notice that the trace edges look very clean with few if any burrs. The lower right looks especially good probably because that's where I zeroed the mill. Hopefully after I flatten out the table, the whole board will look like that.

Mantis 9 is radical departure from my earlier designs--- it has parallel rod axes for example, but I think it turned out very well. Most importantly its the simplest design yet, with only 12 parts! Also I think it might be the first design completely reproducible without machine tools. More details to follow soon on the wiki...

Sunday, March 14, 2010

A glimpse of the future?

One of my major goals for the milling machine project is to design a machine that can be built using only hand tools, a drill press, and a (2D) printer. Laser cutters, ShopBots, and the like are still few in number and relatively expensive to purchase time on. I want a machine for the masses, and that means a machine that can be built using the tools that the masses have.

At the moment I'm calling this machine version 9 of the Mantis mill. Originally V9 was going to be a revision of the V8 mill. Instead my prototype V9 design is radically different than V8. It uses parallel rod axes, it's over-constrained, a lot of it is glued together, and at the moment it only has 17 pieces.

Here's a screenshot of my current progress:

At the moment I'm calling this machine version 9 of the Mantis mill. Originally V9 was going to be a revision of the V8 mill. Instead my prototype V9 design is radically different than V8. It uses parallel rod axes, it's over-constrained, a lot of it is glued together, and at the moment it only has 17 pieces.

Here's a screenshot of my current progress:

Subscribe to:

Posts (Atom)