Saturday, March 27, 2010

Mantis 9 DIY Build Preview

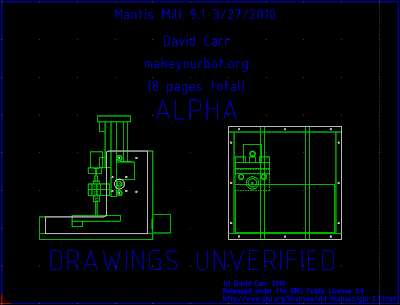

I just finished putting together a set of DIY build templates for the Mantis Mill 9. The basic idea is that with this PDF, a handsaw, a drill press, and a bit of sweat anyone should be able to build their own machine.

PLEASE DO NOT BUILD ANYTHING FROM THESE DRAWINGS YET!

There a several design modifications from my prototype that I want to test before anyone starts cutting wood. That said, the zipfile is on the wiki.

Thursday, March 25, 2010

The future lives!

Today Mantis machine number 9 came to life!

It's first project was a Fabio (arduino compatible) controller like that used in my extruder heater controller.

The board itself came out very well. V9 has reduced slop in the Z axis, an issue that plagued the V8 and earlier machines.

Notice that the trace edges look very clean with few if any burrs. The lower right looks especially good probably because that's where I zeroed the mill. Hopefully after I flatten out the table, the whole board will look like that.

Mantis 9 is radical departure from my earlier designs--- it has parallel rod axes for example, but I think it turned out very well. Most importantly its the simplest design yet, with only 12 parts! Also I think it might be the first design completely reproducible without machine tools. More details to follow soon on the wiki...

It's first project was a Fabio (arduino compatible) controller like that used in my extruder heater controller.

The board itself came out very well. V9 has reduced slop in the Z axis, an issue that plagued the V8 and earlier machines.

Notice that the trace edges look very clean with few if any burrs. The lower right looks especially good probably because that's where I zeroed the mill. Hopefully after I flatten out the table, the whole board will look like that.

Mantis 9 is radical departure from my earlier designs--- it has parallel rod axes for example, but I think it turned out very well. Most importantly its the simplest design yet, with only 12 parts! Also I think it might be the first design completely reproducible without machine tools. More details to follow soon on the wiki...

Sunday, March 14, 2010

A glimpse of the future?

One of my major goals for the milling machine project is to design a machine that can be built using only hand tools, a drill press, and a (2D) printer. Laser cutters, ShopBots, and the like are still few in number and relatively expensive to purchase time on. I want a machine for the masses, and that means a machine that can be built using the tools that the masses have.

At the moment I'm calling this machine version 9 of the Mantis mill. Originally V9 was going to be a revision of the V8 mill. Instead my prototype V9 design is radically different than V8. It uses parallel rod axes, it's over-constrained, a lot of it is glued together, and at the moment it only has 17 pieces.

Here's a screenshot of my current progress:

At the moment I'm calling this machine version 9 of the Mantis mill. Originally V9 was going to be a revision of the V8 mill. Instead my prototype V9 design is radically different than V8. It uses parallel rod axes, it's over-constrained, a lot of it is glued together, and at the moment it only has 17 pieces.

Here's a screenshot of my current progress:

Subscribe to:

Posts (Atom)